Anisotropic epoxy aims for 50µm pitch for wearables

SunRay Scientific has developed a magnetic Anisotropic Conductive Epoxy (ACE) for reliable interconnects on textiles for wearable systems with a pitch as low as 50µm in development.

Ztach ACE provides excellent structural bonding, without encapsulation, even under repeated stretching and washings and has been shown as a scalable assembly process for e-Textile manufacturing in an SMT line.

Electrically functional textiles require maintaining good connections between devices and circuitry printed on, or woven into, the wearable fabric. Adhesion is particularly a challenge between rigid die and the stretching or moving fabric.

Despite notable progress being made in e-Textiles, significant challenges remain relative to functionality, reliability, scalability, and cost. Robust interconnects have been repeatedly noted as a primary challenge in both conformal Flexible Hybrid Electronics and Stretchable e-Textiles.

- Skin-worn ultrasound patch can flex and stretch

- Stretchable substrate film for soft printed electronics

- Electrically conductive die attach epoxy has high Tg

- Graphene filled epoxy

The epoxy allows for simultaneous Z-axis connections of all the devices on a board, sheet or fabric, across large formats. It requires no patterning, no bonding pressure, and can be cured at low temperatures and can adhere to a wide range of substrates, including PET, TPU, various textiles and PCBs.

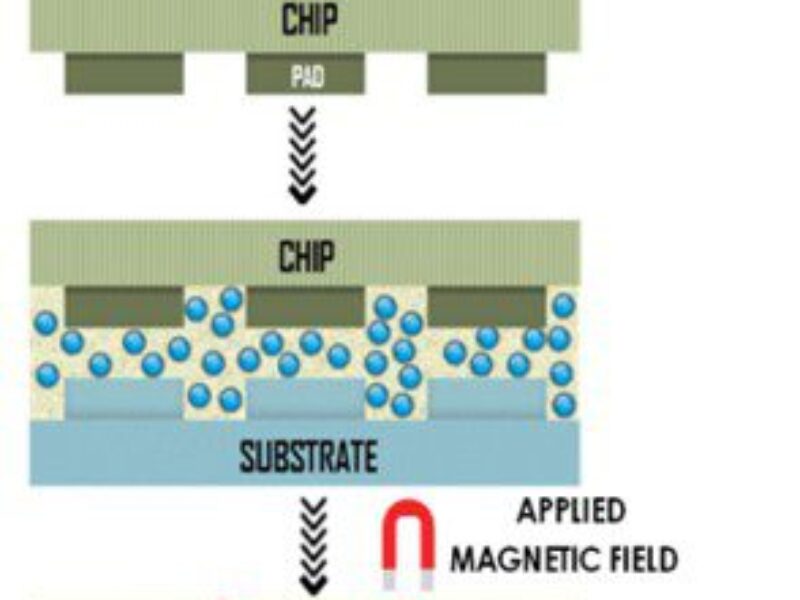

The ACE material is applied in a single stenciling step, followed by magnetizing and curing. The material is applied across the entire footprint of the component to provide both interconnection and structural bonding to the electrical circuitry on the fabric.

It works by the magnetic alignment of ferromagnetic-conductive particles through SunRay’s patented ZMAG magnetic pallet. Once placed on the ZMAG Pallet, the particles immediately align into z-axis “wires” magnetically held in place while the resin is hardened by the curing process. This electrically connects the device to the circuit.

This stabilizes the interconnect sites – the Z-axis columns of aligned particles, held in place by the epoxy resin, allow for flexing of the surrounding textile while maintaining electrical connection

The very low particle filler percentage means the resin creates higher bond strength for the device versus traditional attachment methods and acts as an underfill with conductive Z-axis columns throughout. This creates electrical conductivity at the pad locations and thermal dissipation between while maintaining electrical insulation in the X-Y plane.

As the material acts as its own underfill unlike solder, it provides superior adhesion and shear strength, eliminating the need for a secondary underfill or post-bond encapsulation, and can achieve fine pitch down to 100µm. Less than 50µm pitch is currently in development asays the company.

Most solder connections on a flexible substrate traditionally require the addition of an encapsulant for protection and for maintaining adhesion of the less flexible interconnection joints.

Ztach ACE provides reliability without the need for an encapsulant. , eliminating a manufacturing step and the localized rigidizing created by an encapsulant, with a less bulky product profile. No encapsulant is especially beneficial in LED applications as the clarity of the LEDs are not interfered by the addition of an optically clear covering.

This also avoid issues of the aging of the encapsulant over time, particularly in UV LEDs in medical applications.

The material was developed as part of a project by the Advanced Functional Fabrics of America (AFFOA) with UMASS Lowell to develop a functional e-Textile sheet-to-sheet fabrication and demonstrated scalability on a SMT line. The project, “Reliable High Density Conformal Electrical Interconnects for Dynamically Active Flexible Textile Functionalization”, attached LEDs to woven conductive wire circuits in fabric.

Other articles on eeNews Europe

- Heterogeneous photonics project drives over 100GHz

- MicroLED chip-to-chip links run at 14Gbit/s

- World’s largest quantum cryo system

- Semiconductor market heads for biggest downturn since 2000

- Farewell Pentium and Celeron

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News